Optical Sorting Digital Inspection for Bolts, Screws and Fasteners

30-05-2025

A Robust Quality Control Inspection Service

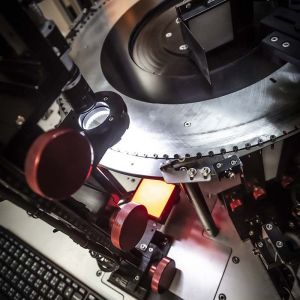

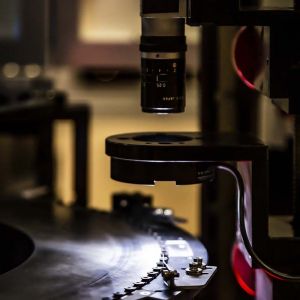

Nufast offers a well-established Optical Sorting and Digital Vision Inspection service designed to enhance quality control across a comprehensive range of standard and bespoke fasteners. Using 360° multi-camera inspection system, our optical sorting service enables precise and repeatable assessment of bolts, screws, rivets, and other components. It supports manufacturers in verifying dimensional compliance, identifying surface defects and reducing non-conformances in production batches.

This solution is applied across multiple sectors, including automotive manufacturing, mechanical engineering and industrial assembly operations.

Application Scope

Nufast’s inspection systems are engineered to sort and inspect a broad spectrum of fasteners, including:

- Bolts: carriage, hex, eye, machine, penta-head, shoulder, socket-head, round-headed, T-head

- Screws: slotted (flat, oval, round), Phillips drive, square drive, CSK, counterbore

- Rivets: solid, tubular, blind, drive, split

- Non-standard fasteners: including items such as Benzo bolts

Inspection Capabilities

Nufast's Optical Sorting and Digital Inspection technology evaluates both dimensional parameters and surface-level defects, providing 360° coverage via high-resolution digital imaging and calibrated lighting:

Dimensional Criteria

- Head height and diameter

- Thread height, major and minor diameters

- Total part length

- Thread angle, direction, and completeness

- Socket concentricity and punch integrity

- Knurling diameter

- Multiple slot detection and slot absence

- Identification of diameter or length mixing

- Bent or deformed parts

- Missing or incomplete manufacturing operations

Surface Defect Detection

- Cracks (including head and top cracks)

- Thread damage and burrs

- Dents and plating inconsistencies

- Surface deformation and contamination

- Socket blackness or breakage

- Presence/absence verification of drive features

This automated, non-contact optical inspection system delivers accurate results at high speeds, suited to both bulk processing and high-tolerance production environments.

Configurability and Throughput

Nufast’s optical inspection systems can be configured to suit a range of part geometries, materials, and inspection standards. Each unit is calibrated to user requirements and supports a range of output speeds for efficient integration into production line requirements or post-production QA workflows.

Automatic rejection of non-conforming parts helps maintain batch integrity while reducing manual handling.

Benefits for Engineering and Manufacturing Operations

- Improved detection of dimensional and cosmetic defects

- Reduced reliance on manual inspection

- Greater process control and part consistency

- Alignment with industry compliance standards (e.g. ISO 9001, IATF 16949)

- Lower risk of downstream failures or rejections

This service is particularly suited for safety-critical and performance-based applications, where fastener integrity is essential.

Technical Oversight and Process Understanding

Nufast provides an Optical Sorting Digital Inspection service with applied understanding of thread geometry, fastener tolerances and material failure modes. Each inspection setup is defined by highly skilled personnel with practical knowledge of cold forming, machining and functional requirements for industrial fasteners.

This technical foundation ensures our Optical Sorting Inspection technology not only detects defects but also aligns with real-world application and client demands.

To find out more about Nufast’s optical sorting and digital vision inspection service, or to discuss your specific fastener inspection requirements, please get in touch with the Nufast team.

Optical Sorting Digital Inspection;

- Precision. Accountability. Assurance.

- Inspection Technology Serves a Range of Industries

- Streamline Production with Nufast’s Optical Sorting Services

- Maximising Efficiency The Benefits of Nufast's Digital Inspection Service